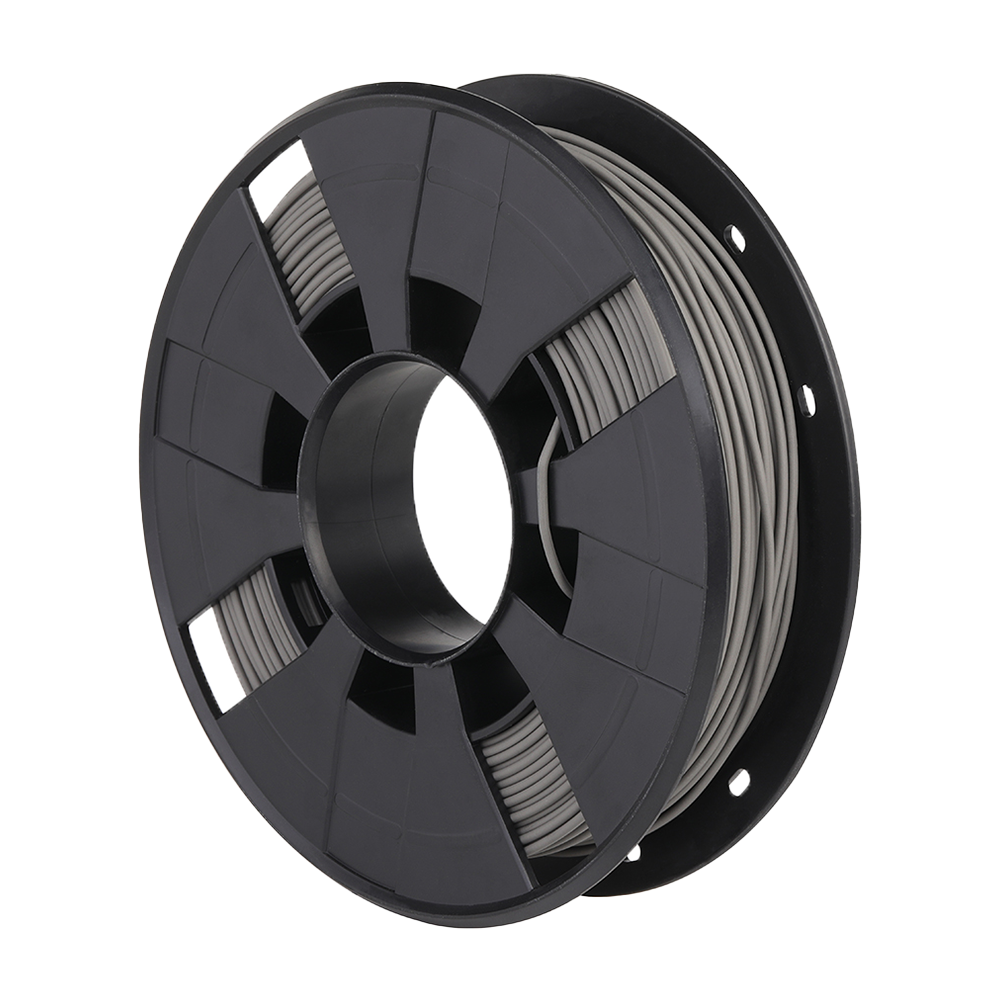

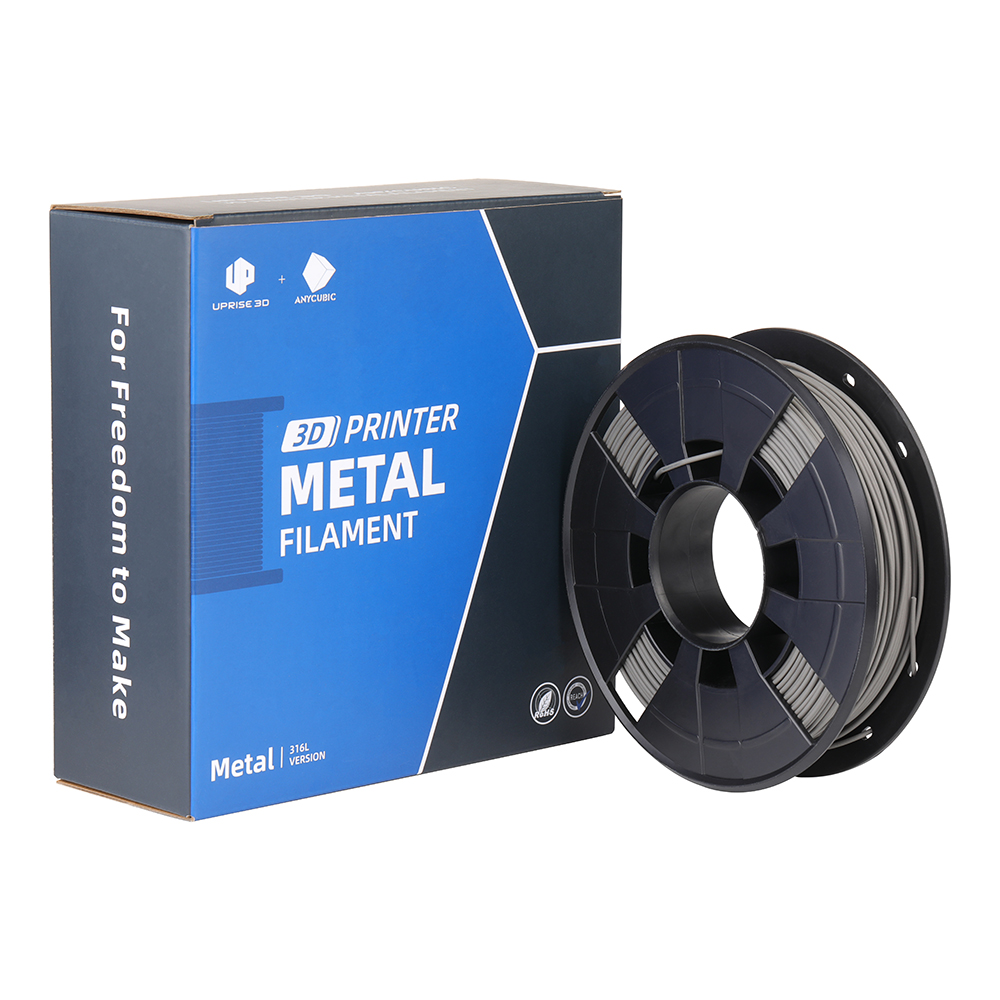

UPFM-316L

UPFM-316L is a new type of metal filament developed by UPRISE 3D, a composite material mixed with metal and polymer binder, which can be used to produce 316L stainless steel metal parts.

UPFM-316L is a new type of metal filament developed by UPRISE 3D, a composite material mixed with metal and polymer binder, which can be used to produce 316L stainless steel metal parts. Through FFF 3D printer, you can quickly print out the preset model green parts layer by layer, and then get the final compact metal parts through debinding and sintering.

316L filament key features

(1) High metal content, easy handling and hard to be broken

(2) Odorless and smoke-free during printing

(3) High quality guarantees stable printing process

Product parameters

| Filament parameters | Material | 316L stainless steel |

| Diameter | 1.75±0.05mm | |

| Length | ~70m | |

| Net Weight | ~750g | |

| Print Temp | 230-240℃ | |

| Hotbed Temp | 85-95℃ | |

| Shrinkage | X,Y:1.2/Z:1.24 | |

| Quality Certification | ROHS/Reach | |

| Properties of sintered parts | Density | 7.93g/㎝³ |

| Yield strength | 197MPa | |

| Tensile strength | 521MPa | |

| Elongation at break | 52.70% | |

| Hardness | 165.7HV1 | |

| Surface roughness | 4.91μm |

Product advantages

The most common method for metal 3d printing is so-called Selective Laser Melting (SLM) technology. However, this method is significant expensive, and requires long term training. Also, related safety issue needs to pay special attention. By using 316L filament, start-up investment is relatively low, as commercial FFF 3D printer is cheap. By simply pressing a few buttons on printer, you can get your metal parts within couple of hours. Using 316L filament, you can print anything from one-off prototype to high volume industrial manufacturing, from customized metal crafts to any complex geometries.

Printed samples

Specification parameters

Product scale

Phone:

(+86)13392420572/(+86)13392421307/(+86)15813725662

E-Mail:

sales@uprise3d.cn