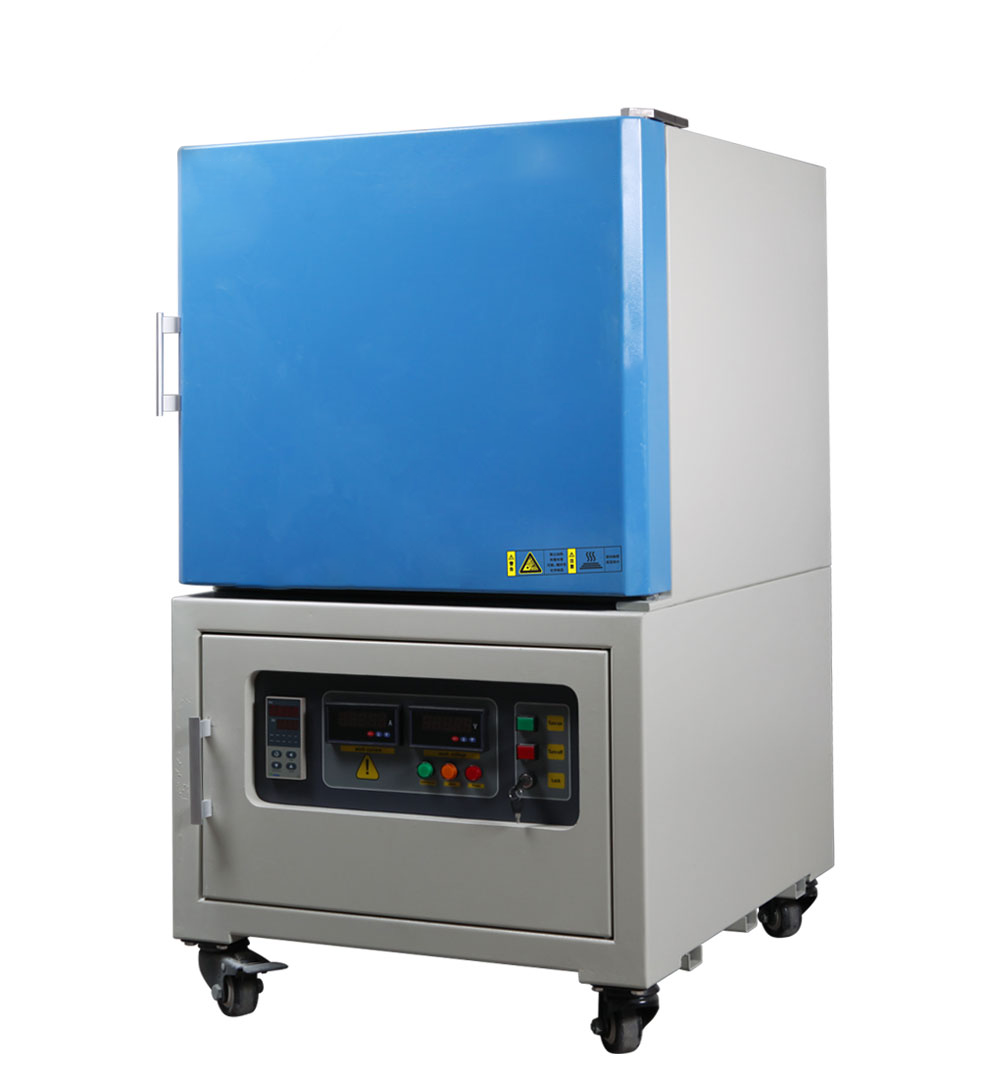

SXL-1700C

Oxidized Ceramic Sintering Muffle Furnace

The green parts printed by oxidized ceramic materials (such as zirconia, alumina, etc.) are often sintered by the 1700℃ muffle furnace to obtain the final compact ceramic parts.

The green parts printed by oxidized ceramic materials (such as zirconia, alumina, etc.) are often sintered by the 1700℃ muffle furnace to obtain the final compact ceramic parts. 1700℃ value-added box-type experimental electric furnace uses high-quality silicon molybdenum Rod as heating element, adopts intelligent temperature control system, controlled by silicon controlled rectifier, and has high temperature control precision; the hearth adopts the assembly structure of high-quality 1700 alumina polycrystalline fiber inorganic material formed by vacuum adsorption of Japanese technology, which can be used for a long time without fracture or collapse. The hearth body is a double-layer furnace shell, equipped with air cooling system, effectively guarantee the surface temperature of the shell.

Product Features

(1)The hearth adopts high-quality 1700 alumina polycrystalline fiber inorganic material formed by vacuum adsorption of Japanese technology, with good thermal insulation performance, durability, high tensile strength, no impurities and high purity, the inner surface of the furnace is coated with imported 1700-degree heat-resistant thermal insulation coating, which can improve the reflectivity and the heating efficiency of the furnace, at the same time prolong the service life of the furnace, and the energy-saving effect is obviously better than that of domestic fiber materials;

(2)The heating element adopts high-quality silicon molybdenum rod, which has high heating efficiency and long service life;

(3)It adopts the design of the assembled furnace. After strict thermal calculation, it is durable and does not collapse. The hearth is equipped with breathing holes, which can reduce the contraction of the hearth and prolong the service life of the hearth;

(4)The left-side open furnace door has the function of opening and power off to ensure the safety of experimental operation;

(5)Reserved air outlet, sintering volatile gas in the experiment process is easy to discharge;

(6)The data conversion interface is reserved and connected with the computer by cooperating with the special software of our company, which can realize the functions of remote control, real-time tracking, historical records, output reports and so on of one or more electric furnaces;

(7)It has overtemperature alarm power-off function and leakage protection measures, and is safe and reliable to operate.

Scope of Application

It is used for powder roasting, ceramic sintering, high temperature experiment, material processing and quality inspection in universities, scientific research institutes, industrial and mining enterprises.

Product parameters

| Equipment model | SXL-1700C |

| Chamber size | D300mm×W250mm×H200mm |

| Equipment weight | 195kg |

| Equipment size | 620mm×680mm×1050mm |

| Equipment power | 6KW |

| Working power | AC220V,50/60Hz |

Specification parameters

Product scale

Phone:

(+86)13392420572/(+86)13392421307/(+86)15813725662

E-Mail:

sales@uprise3d.cn