"Uprise 3D Team" is the first team engaged in 3D printing research based on Powder Metallurgy Technology in China. The core team is from the Powder Metallurgy Research Institute of Central South University and the School of Materials, University of New Wales, Australia. The founders Wu Min and Liu Ye graduated from the same University, they have been classmates for 7 years and have a common tutor, Professor Xiong Xiang. Professor Xiong is a world famous scientist in the field of materials. In 2015, the team invented a new technology. It is the first time in China, the "indirect 3D Printing technology" Powder Extrusion Printing technology based on the combination of "additive manufacturing" and "high-temperature sintering" has been proposed. This technology is named Powder Extrusion Printing, named for PEP technology by Professor Xiong Xiang. And then Shenzhen Uprise 3D Technology Co., Ltd was established in June 2017, which encountered many difficulties at the beginning, but was lucky to get angel investment. After several years of development, it has more than 30 patents and equipment has been developed into the third generation. They are young and passionate company focusing on technology development and innovation, which are committed to developing indirect metal/ceramic 3D printing technology and to providing best services and excellent 3D printing solutions worldwide.

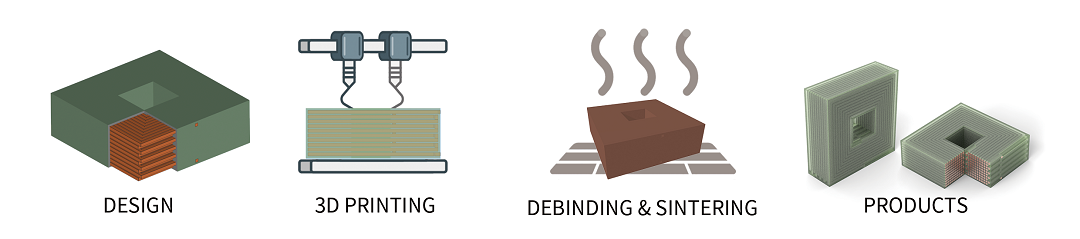

Unlike selective laser sintering (SLS) and selective laser melting (SLM), PEP technology is a revolution method, since it integrates 3D printing technology and traditional powder metallurgy industry together. The first step is to obtain green part by 3D printing, the second step is debinding process, majority of binder polymers are removed and as-printed green part turns into brown part, and the last step is that through sintering, metal/ceramic particals fuse together to dense and final metal part can be obtained.