Shenzhen Uprise 3D Technology Co., Ltd. was established in June 2017, focusing on the R & D and production of metal/ceramic indirect 3D printing equipment and materials. The core team is from the Powder Metallurgy Research Institute of Central South University and the School of Materials, University of New Wales, Australia. With the knowledge background of powder metallurgy, we developed the so-called powder extrusion printing (PEP) which combines advanced 3D printing technology with traditional powder metallurgy technology. Uprise 3D is the pioneer and leader of metal/ceramic indirect 3D printing technology.

With the help and support of Alumni Association of Central South University in Shenzhen, UPRISE 3D is developing rapidly. On November 26th, 2021, led by Cai Guoqiang, the president of the Alumni Association of Central South University in Shenzhen and the director of the Development Committee of the Alumni Association, Zheng Jie, the president of Shenzhen Research Institute of Central South University, Tang Weiling, the executive chairman and secretary general of the alumni association, Zeng Lianbin, the executive vice president of the alumni association, Zhang Xin, the vice president of the alumni association, Liao Lin, the office director of Shenzhen Research Institute of Central South University, Li Lunjun, the director of the alumni association and the president of world investment, Yang Zhicheng, the director of the alumni association, Wang Zeshen, the director of the alumni association, Wei Tianyu, an alumnus of Central South University, working in Mushroom Artificial Intelligence Technology (Shenzhen) Co., Ltd., Wu Bing, the full-time secretary of the alumni association, Mr. Wang Weimin, the vice president of Elitimes Asset Management Co., Ltd., and Dr. Li Wei visited UPRISE 3D together for guidance.

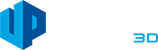

Fig.1. Wu Min, general manager of UPRISE 3D introduces our company to alumni.

Wu Min, general manager of UPRISE 3D, introduced "low cost metal/ceramic indirect 3D printing technology and its application" to alumni. In April, 2016, the UPRISE 3D team first put forward the indirect 3D printing technology of "3D printing + Powder Metallurgy". At that time, no matter at home or abroad, no company with the same technical route could be found. It was not until 2017 that it was reported for the first time in China that Desktop Metal in the United States put forward the same technical solution. The advancement of UPRISE 3D technology successfully attracted investors. In May 2017, the UPRISE 3D team obtained angel investment from venture capital institutions, and officially operated in June of the same year. We have expanded our team to accelerate the industrial layout and application of metal & ceramic indirect 3D printing technology. In the first half of 2021, UPRISE 3D obtained the strategic investment of Miraclplus founded by Dr. Lu Qi, formerly YC China.

After four years of hard work, UPRISE 3D has successively released industrial 3D printer UP-R200, desktop 3D printer UPS-240, large-size independent double-nozzle 3D printer UPS-556, industrial independent double-nozzle 3D printer UPS-250, stainless steel pellet, zirconia pellet, tungsten alloy pellet, 316L metal filament and other products, which constantly breaks through in the aspects of equipment stability, printing speed, printing precision and product performance. It creates 3D printing "hard technology" with core technical barriers, and establishes a comprehensive research and development system from equipment, materials, software and control system, printing technology to post-processing, which can quickly respond to market demands and bring highly cost-effective products and service experience to customers.

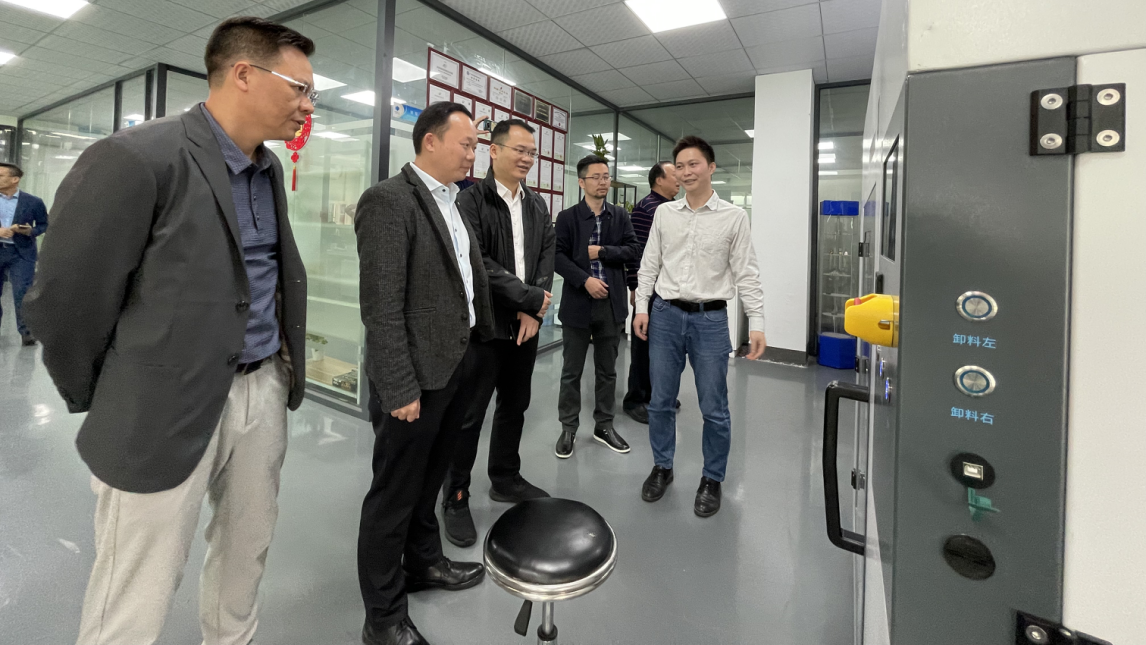

After listening to the report, the alumni came to the workshop to visit the printing equipment, debinder and sintering furnace. The founder of UPRISE 3D explained the detailed technological process of PEP technology and the working principle of 3D printing equipment to the alumni.

Fig.2. Alumni are visiting the printing equipment.

Fig.3. Alumni are visiting the assembled equipment.

Fig.4. Alumni are visiting the sintering furnace.

After the visit, President Cai spoke highly of the pragmatic ability of people in Central South University, and encouraged us to continue our efforts, focusing on indirect 3D printing, constantly breaking through and innovating in technology, and promoting the industrialization of 3D printing. He wishes UPRISE 3D can grow vigorously and prosper day by day.

Finally, we would like to thank the Alumni Association of Central South University in Shenzhen for the visit, who gave many valuable suggestions that can help us walk faster and more smoothly on the way forward. UPRISE 3D will remember the cultivation of alma mater, sublimate intelligent manufacturing in 3D printing industry, and develop into a 3D printing technology oriented to large-scale production and the next generation product design and manufacturing scheme.